A BULLETIN DEALING WITH ISSUES FOR DENTAL HEALTH PROFESSIONALS

Inside This Issue

1. Increase Your Attachment Business

2. Introducing Bredent’s New Microbur

3. Revisiting the Hollow Pontic

4. Next Scheduled Attachment Seminar

5. Setting Goals For 1999

Would you like to increase your attachment business? For the users of metal plastic attachments such as the Bredent’s VKS Snap attachment. Bredent makes four colour marketing brochures for dental health professionals available to dental laboratories who want to use them for all types of mailings. A patient education booklet provides the laboratory with information to offer to dental professionals to promote the use of the Bredent attachments systems. Using brochures in mailings as statement stuffers creates recognition of the product. It plants a seed in the dental professionals mind. Then when they call up to ask questions, you say “we are using Bredent attachments” “Have you heard of them”. And of course they have. There are also other colour pamphlets that show pictures of the technical aspects of the various attachments and part numbers for simple ordering. The dental professional can also have access to an instructional sheet that outlines clinical aspects. There is also a video showing some of the different attachments that Bredent produces. Not to mention a attachment specialist who can discuss treatment planning, techniques and tips For more information and how you can benefit from this service, just call Bredent’s technical director, Peter T. Pontsa, R.D.T. at 1-800-859-7589 or e-mail us at dent-line of canada inc.

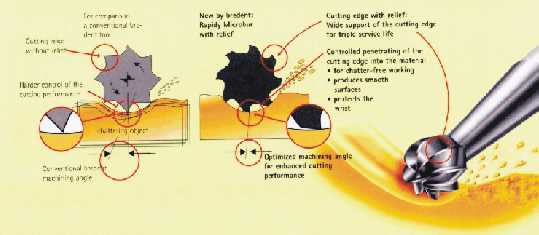

Introducing a revolutionary new concept in carbide tooling that can “Triple” service life.

The research and development engineers at Bredent’s facilities in Germany have developed a macro bur capable of extending service life up to three times the conventional cuts from Bredent’s carbides. The micro bur is provided with relief on the blades in an additional manufacturing process. The wide relief supports the sharp edge to avoid wearing of the edges. This way the service life is extended. The optimized machining angle of the blades create an enhanced cutting performance by improving the control of the cutting edge when engaging dental materials. This improved control makes for chatter-free cutting, producing smooth surfaces while reducing overall vibration through the hand piece. Thus protecting the wrist from occupational damage. The diagrams will explain the new design feature of Rapidy Microbur. For a catalogue on the Bredent carbides contact Dent-line at 1-800-859-7589

The hollow pontic technique was developed in order to combat the problems encountered in conventional crown and bridge fabrication. Here are some that we have seen such as contraction cavities, stresses, in homogeneity, cracked connectors, instability, differences in thermo expansion during firing between crown and pontic and excessive weight when using precious metals. The object of this technique is primarily to produce crowns and pontics with balanced volumes after casting. In order to achieve this, the pontics were designed to be hollow. During solidification of solid pontics, a contraction process is initiated which leads to metal being drawn away from the thin sectioned, adjacent crown to the centers of the solid pontics. Therefore in cases involving large pontic construction, surface defects such as porosity’s and contraction cavities can be caused around the sprue. What will occur in any case is that the cast structure of the connectors between the separate pontics will be inhomogeneous. This together with micro-fine or even visible cracks, can lead to an awkward loss of stability. Another development to offset porosity and improve grain structure of the metal is a “Square” sided sprue wax called quadro. Research confirms that round conventional sprues create turbulence in the metal as it spins through the sprue channel. The square sided quadro sprue prevents the circumferential spinning and forces the metal to flow into the corners reducing turbulence in the sprue channel. The result is a finer and condensed grain structure of the metal. Hollow pontic wax units provide contraction and stress free metal sub structures. As the volumes of the cast crowns and pontics are well-balanced thermo expansion and many other problems disappear. Also ceramic occlusal surfaces can be refined to provide good aesthetics as fissures can be carved much deeper than with solid pontics, while reducing 58 % of the metal used for pontics. Stefan Borenstein RDT says the best way to fill a hollow pontic is to prebake little rods of varying sizes using opaque mixed with dentin. Then insert these rods into the hollow pontic at the wax up stage and cast your alloy directly onto them. This saves time for the ceramist to fill the hollow and is very productive and cost effective. Thank You Stefan. Another use for hollow pontics is implant related. When waxing up single units or bridges over plastic cylinders like the UCLA abutment, just slip a suitable sized hollow pontic over the cylinder and fill in any voids between the wax pontic and the cylinder wall This will cut waxing time considerably and is cost effective. The hollow pontics come in 1×4 blocks or in single form. The Quadro wax sprues and pontics are available from Bredent. For a free sample please contact Dent-line of Canada at 1-800-859-7589.

Dent-line of Canada will sponsor a presentation on various attachments and screw retained bridge work as well. The seminar will take place at the 25 th Anniversary of Technorama 1999 to be held Friday March 26,1999 and Saturday, March 27,1999 at The Inn On The Park, 1100 Eglinton Ave. East, Toronto, Ontario, M3C 1H8. Continuing education points would apply. Plan to attend a once a year opportunity to participate in a two day program designed just for you! For additional information call 1-800-859-7589

Write down those goals – Dreamers fantasize; achievers plan. Be Specific, Make them Measurable, Take Action, Make them Realistic, Develop a Time Plan. If you follow the above, you will be S-M-A-R-T. Write down your personal, family and business goals, and do your best to get there. Nothing feels better than achieving those goals.

Source: Toastmaster, Voice of Muskoka Newsletter; District 60 – Club #1940

Volume 2 Issue 4, December 1997