This prefabricated unit facilitates fabrication of a sectioned bridge with occlusal screw.

|

The titanium screw has a hexagonal socket to facilitate tightening and loosening. |

|

The circumferential ring marks the maximum level to which it can be shortened, |

|

Premanufactured abutment.

|

|

|

|

|

|

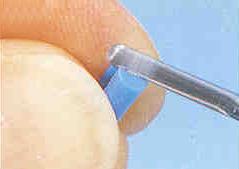

| The paralleling mandrel positions the sectioning attachment correctly. |

The design and minimal dimensions of the threaded sleeve in the sectioning attachment enable it to be adapted to the papillae as required. |

The threaded sleeve is made of a cast-on alloy and can be used with any gold or semi-precious alloy. |

The retention rod should be coated with colloidal graphite and retains the threaded sleeve precisely in the investment material. |

The section connecting the attachment to the coping is rounded, has a diameter of 1.0 mm and can be trimmed accurately with a 1.0 mm rotary cutter if required. |

|

|

|

|

|

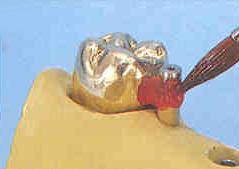

| The circumferential ledge on the locking ring marks the level to which the screw and locking ring can be reduced. |

To ensure that the locking ring is fixed in place securely, the outer section must be moulded with Pi-Ku-Plast brush-on resin. |

The exterior design of the locking ring which consists of a cast-on gold alloy, ensures that it is retained securely in resin. |

The bridge patter is waxed up onto the resin outer section. |

The titamium screw can be ground to blend it into the occlusal surface. |