A BULLETIN DEALING WITH ISSUES FOR DENTAL HEALTH PROFESSIONALS

Inside This Issue

1. Exakto-Form Model Resin Profiled

2. Wear Study of Attachments

3. Q and A on Compatible Implant Parts

4. New Product from Bredent, page 2

B io mechanical considera- tions such as loading and force distribution on to implants and roots effectuates controversy regarding the best retention mechanism (rigid or stress breaking) and the best retention device for over denture connection (single anchors or bar splits). Findings indicate that the retention choice be selected according to the specific clinical and individual needs of the patient. It has been noted that preservation of root structure can prevent or a least delay ridge atrophy. Over denture literature describes the concepts back to Dr. Ledger of the U.K. 1856. A further study by M.Wichmann, and W. Kunze compares the wear of prefabricated precision attachments. The aim of this laboratory study was to measure the effect on the forces required to engage and disengage prefabricated precision attachments. Five different types or prefabricated attachments were selected for testing, Three attachments (Bredent SG, mini SG and PreciVertix) had removable plastic inserts. Two conventional attachments consisted of metal female and male components. Five specimens of each type were exposed to continuous stress of 10000 cycles of engaging and disengaging using an axial line of draw. The retentive forces were measured simultaneously at each loading cycle. A solution representing the electrolyte component of saliva was flowing over the female and male components to remove the abraded material. During the first 1000 loading cycles the retentive force of the conventional metal attachments decreased from an initial 7 Newton’s to 3 respectively 4 Newton’s. During the next 9000 loading cycles the retentive forces decreased steadily to a mean value of 3 Newton’s. By comparison, all attachments with plastic female inserts showed nearly no decrease in retentive force during 10000 loading cycles. Depending on the type of plastic insert the retentive force was between 2 Newton’s and 30 Newton’s. In conclusion the conventional metal attachments showed significant wear and an extensive loss of retention. In contrast to this, attachments with plastic inserts showed only negligible amounts of wear and the most consistent retentive force. Furthermore the study included wear-induced loss of retention in attachment-retained dentures poses a major clinical problem. To counteract this unwanted effect, most prefabricated precision attachments can be activated to restore wear-induced loss of friction. This is achieved by design elements such as resilient metal tongues, partially or completely slotted male components, set screws, or replaceable plastic wearing parts. The aim of this comparative study was to assess thewear behavior of different prefabricated attachments and the effectiveness of activation in restoring wear-induced loss of friction and retention. Attachments of various designs were subjected to alternating load cycles in a wear simulator. Five specimens of attachments were subjected to the wear test. Theses consisted of a total of four consecutive cycles of 10000 respectively 5000 separating and joining movements each. At baseline, each attachment was activated to have a retentive force of 7 Newton’s. In each of the four consecutive cycles, the attachments with metallic surfaces showed a rapid loss of friction of approximately 60 to 70 % even after forced activation to retentive forces between 15 and 20 Newton’s, the same rapid loss of friction was found. The attachments with plastic inserts by contrast showed only negligible reductions in the required engaging / disengaging forces even after 10000 wear cycles. Although there was only little loss of friction in the attachments with plastic inserts, activation or replacement of the plastic insert was effective to restore friction to the level present in the beginning of each load cycle. Source: www.zahnheilkunde and Peter T. Pontsa, R.D.T.

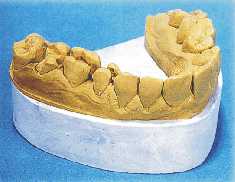

VKS 3 Mini Attachment

This model resin was developed by Bredent as a dual component model material, based on polyurethane, for fabricating extremely precise dental models. Because of its very low viscosity, it is easily poured into the impression without trapping air bubbles. This cost effective model resin features absolutely precise reproduction of surfaces, dimensional stability and unequaled precision of fit, with no expansion whatsoever and is exact to .175 shrinkage. The hardened resin can be sawed, drilled, and trimmed easily. Components A and B are mixed together to produce a light green colored model. There are also color concentrates available. Exakto-Form comes in a set of 6 x 50 gram each of component A and B. Also available is Exakto-Form insulating liquid for easy separation from silicone impression materials. For more informatiion, please call Dent-Line at 1-800-859-7589 or e-mail us at inforn@dent-line.com.

This model resin was developed by Bredent as a dual component model material, based on polyurethane, for fabricating extremely precise dental models. Because of its very low viscosity, it is easily poured into the impression without trapping air bubbles. This cost effective model resin features absolutely precise reproduction of surfaces, dimensional stability and unequaled precision of fit, with no expansion whatsoever and is exact to .175 shrinkage. The hardened resin can be sawed, drilled, and trimmed easily. Components A and B are mixed together to produce a light green colored model. There are also color concentrates available. Exakto-Form comes in a set of 6 x 50 gram each of component A and B. Also available is Exakto-Form insulating liquid for easy separation from silicone impression materials. For more informatiion, please call Dent-Line at 1-800-859-7589 or e-mail us at inforn@dent-line.com.

Q. The Replace TM 4.3 mm series platform is 0.3 mm wider than the Bredent VKS-oc-rs 4 mm platform abutment. Is there a clinical disadvantage?

A. No. The VKS-oc-rs abutment is slightly smaller when screwed down. Titanium being rather soft, it is possible to rubber wheel the edge smooth on an analogue before placing the abutment. Tissue will form over the joint and cover it.

Q. I want to use Replace TM to a direct implant over denture abut ment. But the implants are too angled for the O rings. What can I do?

A. By using Bredent VKS-oc-rs replacement abutments, they can accept deviations up to 15 degrees to the planned angle of insertion. The retention sleeves give three different frictions if required.

Q. My patient has a 0.5mm ( or .06 mm) platform and I want to use direct to over denture abutments. What’s available?

A. The VKS-oc-rs abutments are available for 0.5 and 0.6 mm platforms. Although 0.6 mm are not generally used for that purpose, it can be utilised if necessary.

Q. Can the VKS-oc-rs compatible abutments designed for Replace TM implant be used on the Steri-Oss 0.5 and 0.6 mm implant platform?

A. Yes.

Q. Are there any competitive components compatible with Replace TM, Steri-Oss, Branemark or 3i?

A. Yes the Bredent VKS-oc-rs replacement abutment components fit 0.4, 0.5, and 0.6 mm hex platforms, with the advantage of multi retentive load bearing replacement sleeves. For info call Dent-line at 1-800-859-7589

New milling burs have been developed for non precious metals. They will be available in 1.5 and 2.3 mm sets. Contact Dent-Line of Canada at 1-800-859-7589.