540 0102 4 – Comp. A & B 1,300 grams each

540 0102 5 – Comp. A & B 7,500 grams each

Material Saftey Data Sheet

|

|

|

|

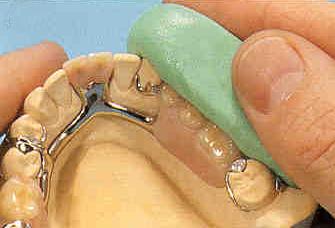

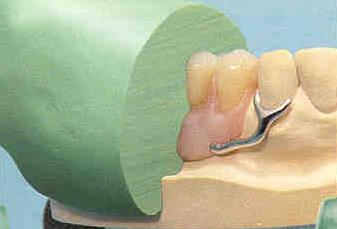

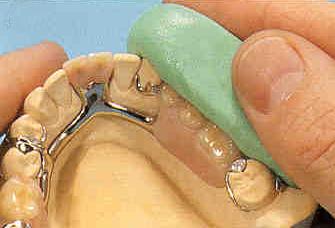

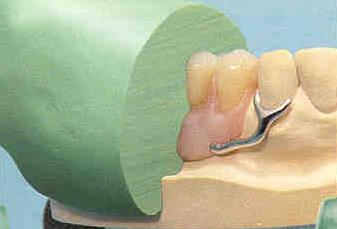

| The Exaktosil Plus kneading silicone is mixed from two components, A & B in a ratio of 1:1. | Homogeneous processing of the two components is ensured by kneading them for approx. 30 sec. until a uniform colour. | Exaktosil kneading silicones have a particularly soft consistency for precise adaptation of the material. | The fine reproduction of details and high stability of the Exaktosil kneading silicones provide accurate matrices. |

The condensation-linking silicone.

The economic alternative

540 0102 9 – Assortment; 1,250 base material, 50 gram hardener paste.

540 0103 0 – Assortment; 7,500 base material, 6 x 50 gram hardener pastes.

Material Saftey Data Sheet

|

|

|

|

| A measuring spoon of Exaktosil C kneading silicone is mixed with 3 cm. of hardener paste. |

Homogenous process of the two components is ensured by kneading them for approx. 30 secs. for homogenous colour. |

Exaktosil kneading silicones have a particularly soft consistency for precise adaptation of the material. |

The fine reproduction of details and high stability of the Exaktosil kneading silicones provide accurate matrices. |

Exakto-Form Kit – A model resin for accurate reproduction and maximum edge stability.

Order No: 52000280 – 6 x 50 g. each of Component A & B.

Material Saftey Data Sheet Component A

Material Saftey Data Sheet Component B

Order Number: 52000210

Material Saftey Data Sheet

|

|

|

|

|

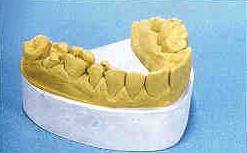

| Prior to mixing, each component must be stirred so that a homogeneous mixture is obtained. | Add component A to component B; empty tin completely. | Mix Exakto-Form approximately 30 seconds until a uniform colour is obtained. | Two twins of Exakto- Form are sufficient to produce 2 – 3 complete dental arches. | The material can be removed after 30 mins. Final hardness is achieved after 10 mins. Then the model can be trimmed. |

|

|

|

|

|

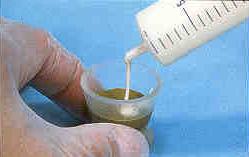

| If a base for the model is to be made with Exakto-Form, the model must be previous insulated with Insulating Liquid. | Due to is high edge stability, Exakto-Form is perfectly suitable for precision fit bridge and crown work. | Any technique can be used for sawing Exakto-Form models. Here we are using our Giflex. | If smaller quantities are required, fill component A and B into a separate syringe. | Fill equal quantities of Exakto-Form into a silicone beaker (approx. 2 ml for one die) and mix to obtain a homogeneous material. |

Investment Marker

|

|

|

| Investment Pen; 330 0115 0

Material Saftey Data Sheet |

All the necessary information is recorded. | At 1100 Deg. Celsius information remains readable. |